Difference between revisions of "Laser Cutters"

m |

m (→Servicing) |

||

| Line 285: | Line 285: | ||

Our beam leaves the laser at an angle, this is ''probably'' due to minor mirror misalignment. Have a look at [https://www.youtube.com/watch?v=XRizHrFSCwc this video] to understand why (1:15 or so for the pretty pictures) of why slight wonkiness matters so much to exit angle. | Our beam leaves the laser at an angle, this is ''probably'' due to minor mirror misalignment. Have a look at [https://www.youtube.com/watch?v=XRizHrFSCwc this video] to understand why (1:15 or so for the pretty pictures) of why slight wonkiness matters so much to exit angle. | ||

| − | Alignment videos; coarse alignment https://www.youtube.com/watch?v=5YvOqH44n6c and the more relevant part 2 which deals with the 'mirror' stage of the problem https://www.youtube.com/watch?v=pl6dAWOkksM . Actual ''mirror'' alignment | + | Alignment videos; coarse alignment https://www.youtube.com/watch?v=5YvOqH44n6c and the more relevant part 2 which deals with the 'mirror' stage of the problem https://www.youtube.com/watch?v=pl6dAWOkksM . Actual ''mirror'' alignment, eg squaring the beam path to the axis: https://www.youtube.com/watch?v=Vl6QKlwRKlk . |

Laser MOT; https://www.youtube.com/watch?v=wupSN8mXlus | Laser MOT; https://www.youtube.com/watch?v=wupSN8mXlus | ||

Revision as of 06:08, 22 March 2018

Contents

Usage

Use of this equipment is strictly for members only, before use, users MUST attend an induction. Incorrect use of this equipment can cause serious harm or death, if you are not inducted do not touch.

A user guide can be found here

Note that if you see smoke pooling aggressively in the cutter this may indicate that the fan covers have jammed - consult Mr Laserducky to verify this. Power cycle the extraction fan to hopefully fix it.

Protip: if smoke is solely departing from the top of your workpiece, you probably haven't fully cut through it. Check before removing it!

Using more than 60% power is highly inadvisable. The tube is underrated so that is almost at its maximum. The difference between 60% and 70% is minimal, and over 70% is overdriving the tube, eg it's at maximum output and you're just throwing more power at it anyway. Using more than 70% power is a really bad idea and you shouldn't be doing it ever.

The plastic window in the lid absorbs the cutting beam's particular wavelength, so from that view it is safe to watch - however the light generated by the act of cutting can sometimes be bright enough to cause concern, much like burning magnesium or similar. It may also be worth mentioning that we have no idea what class of laser the guide beam is, and it often reflects at the user, unhindered by the lid. Staring at either for too long is inadvisable.

Software

Software is Windows only, Windows XP through to Windows 10 is currently supported - it is installed already on both of the PCs. The software required is RD Works and can be downloaded from here

The design file can be designed in almost any vector graphics program, File formats known to work are:

- dxf - Autocad, Draftsight, Inkscapce etc.

The file should be layers with layers setup for each type of cut, We would recommend three layers as follows:

- Cutting, all inner cuts

- Cutting, the outer perimeter, i.e. the last cut so the material does not fall out before all the inner cuts are complete

- Etching, anything to be etched, i.e. text and images.

Once loaded into RD Works, the layers can be ordered to ensure the outer cut is last.

Settings for common materials

These date from before the new PSU, user beware! 30% of 'something' is now 30% of 'something else'!

- 3mm Acrylic

- Cut

- Power = 30 %

- Speed = 10mm/s

- Etch

- Power = 20 %

- Speed - 200mm/s

- Cut

- 3mm ply

- tbc

- 6mm ply

- tbc

- Cardboard

- Cut

- Power = 30%

- Speed = 20mm/s

- Note that the offcuts from this fall and end up igniting later! Ensure you remove them.

- You may need to disable the blower, to prevent embers being fanned into flames.

- Note harder that corrugated cardboard loves to catch fire when the blower blasts air through the channels. Must be watched constantly!

- Cut

Text to Etch

- Create your cutting file

- Open in Inkscape

- Select text (Arial Bold works well), click Path / Object to Path

- Save as dxf, untick "use LWPOLYLINE type of line output" on the Options box

- Import DXF file into RD Works

Materials

Materials NOT to cut

| Material | DANGER! | Cause/Consequence |

|---|---|---|

|

Emits chlorine gas when cut! | Don't ever cut this material as it will ruin the optics, cause the metal of the machine to corrode, and ruin the motion control system. |

| Thick ( >1mm ) Polycarbonate/Lexan | Cuts very poorly, discolours, catches fire | Polycarbonate is often found as flat, sheet material. The window of the laser cutter is made of Polycarbonate because polycarbonate strongly absorbs infrared radiation! This is the frequency of light the laser cutter uses to cut materials, so it is very ineffective at cutting polycarbonate. Polycarbonate is a poor choice for laser cutting. |

| ABS | Melts | ABS does not cut well in a laser cutter. It tends to melt rather than vaporize, and has a higher chance of catching on fire and leaving behind melted gooey deposits on the vector cutting grid. It also does not engrave well (again, tends to melt). |

| HDPE/milk bottle plastic | Catches fire and melts | It melts. It gets gooey. Don't use it. |

| PolyStyrene Foam | Catches fire | It catches fire, it melts, and only thin pieces cut. This is the #1 material that causes laser fires!!! |

| PolyPropylene Foam | Catches fire | Like PolyStyrene, it melts, catches fire, and the melted drops continue to burn and turn into rock-hard drips and pebbles. |

| Fiberglass | Emits fumes | It's a mix of two materials that cant' be cut. Glass (etch, no cut) and epoxy resin (fumes) |

| Coated Carbon Fiber | Emits noxious fumes | A mix of two materials. Thin carbon fiber mat can be cut, with some fraying - but not when coated. |

Laser safe materials

The laser can cut or etch. The materials that the laser can cut materials like wood, paper, cork, and some kinds of plastics. Etching can be done on almost anything, wood, cardboard, aluminum, stainless steel, plastic, marble, stone, tile, and glass.

Cutting

| Material | Max thickness | Notes | WARNINGS! |

|---|---|---|---|

| Many woods | 6mm (1/4") | Avoid oily/resinous woods. Hardwood/heavy duty cutting will require many passes and the gulley thus formed is a firetrap. Consider 'etching' cuts instead with a cut setting but low power and high speed, then band/jig/scrollsawing. | Be very careful about cutting oily woods, or very resinous woods as they also may catch fire. |

| Plywood/Composite woods | 6mm (1/4") | These contain glue, and may not laser cut as well as solid wood. | |

| MDF/Engineered woods | 6mm (1/4") | These are okay to use but may experience a higher amount of charring when cut. | |

| Paper, card stock | thin | Cuts very well on the laser cutter, and also very quickly. | |

| Cardboard, carton | thicker | Cuts well but may catch fire. Remove all fragments! Blower may need disabling. | Watch for fire. |

| Cork | 6mm (1/4") | Cuts nicely, but the quality of the cut depends on the thickness and quality of the cork. Engineered cork has a lot of glue in it, and may not cut as well. | Avoid thicker cork. |

| Acrylic/Lucite/Plexiglas/PMMA | 12mm (1/2") | Cuts extremely well leaving a beautifully polished edge. | |

| Thin Polycarbonate Sheeting (<1mm) | <1mm | Very thin polycarbonate can be cut, but tends to discolour badly. Extremely thin sheets (0.5mm and less) may cut with yellowed/discoloured edges. Polycarbonate absorbs IR strongly, and is a poor material to use in the laser cutter. | Watch for smoking/burning |

| Delrin (POM) | thin | Delrin comes in a number of shore strengths (hardness) and the harder Delrin tends to work better. Great for gears! | |

| Kapton tape (Polyimide) | 1.5mm (1/16") | Works well, in thin sheets and strips like tape. | |

| Mylar | 1.5mm (1/16") | Works well if it's thin. Thick mylar has a tendency to warp, bubble, and curl | Gold coated mylar will not work. |

| Solid Styrene | 1.5mm (1/16") | Smokes a lot when cut, but can be cut. | Keep it thin. |

| Depron foam | 6mm (1/4") | Used a lot for hobby, RC aircraft, architectural models, and toys. 1/4" cuts nicely, with a smooth edge. | Must be constantly monitored. |

| Gator foam | Foam core gets burned and eaten away compared to the top and bottom hard paper shell. | Not a fantastic thing to cut, but it can be cut if watched. | |

| Cloth/felt/hemp/cotton | They all cut well. Our lasers can be used in lace-making. | Not plastic coated or impregnated cloth! | |

| Leather/Suede | 3mm (1/8") | Leather is very hard to cut, but can be if it's thinner than a belt (call it 1/8"). Our "Advanced" laser training class covers this. | Real leather only! Not 'pleather' or other imitations! |

| Magnetic Sheet | Cuts beautifully | ||

| NON-CHLORINE-containing rubber | Fine for cutting. | Beware chlorine-containing rubber! | |

| Teflon (PTFE) | thin | Cuts OK in thin sheets. See https://www.ulsinc.com/materials/teflon ; the issues listed in https://en.wikipedia.org/wiki/Polymer_fume_fever should not matter because our lasers are fully vented and exhausted. | |

| Carbon fiber mats/weave that has not had epoxy applied |

Can be cut, very slowly. | You must not cut carbon fiber that has been coated!! | |

| Coroplast ('corrugated plastic') | 6mm (1/4") | Difficult because of the vertical strips. Three passes at 80% power, 7% speed, and it will be slightly connected still at the bottom from the vertical strips. | Due to PSU issues we probably don't want to be cutting this currently. Also ensure it is polypropylene plastic, not PVC! |

Etching

All the above "cuttable" materials can be etched, in some cases very deeply.

In addition, you can etch:

| Material | Notes | WARNINGS! |

|---|---|---|

| Glass | Green seems to work best...looks sandblasted. | Only FLAT GLASS can be engraved in our cutter. No round or cylindrical items. |

| Ceramic tile | ||

| Anodized aluminium | Vaporizes the anodization away. | |

| Painted/coated metals | Vaporizes the paint away. | |

| Stone, Marble, Granite, Soapstone, Onyx. | Gets a white "textured" look when etched. | 100% power, 50% speed or less works well for etching. |

Photo style engraving of mdf, this was my process

Import image

Select it then hit the BMP button middle top

Set dpi to 300 Set dither Set net graphic 100 lines,

Preview on view, if okay then apply to source

Set min power to say 25% max power 50% speed 200mm, worked for MDF, with good results

Test files

We have carried out a number of tests on common materials, we will publish the settings is the software section above, if you wish to carry out further tests, the test files can be downloaded from Boss Laser.

Suppliers of materials

Other Learning Resources

Servicing

Lens and the mirrors need cleaning, ideally we need lint-free cloth for this. Cotton can scratch the molybdenum (assuming that is what we have). Note that the lens itself is likely zinc selenide, which is both toxic and fragile.

Our beam leaves the laser at an angle, this is probably due to minor mirror misalignment. Have a look at this video to understand why (1:15 or so for the pretty pictures) of why slight wonkiness matters so much to exit angle.

Alignment videos; coarse alignment https://www.youtube.com/watch?v=5YvOqH44n6c and the more relevant part 2 which deals with the 'mirror' stage of the problem https://www.youtube.com/watch?v=pl6dAWOkksM . Actual mirror alignment, eg squaring the beam path to the axis: https://www.youtube.com/watch?v=Vl6QKlwRKlk .

Laser MOT; https://www.youtube.com/watch?v=wupSN8mXlus

Once we have an ammeter, we need to have a fiddle to work out our power/output curves. https://www.youtube.com/watch?v=nZuatc3eIgU and https://www.youtube.com/watch?v=j5cIFxGu_1g for more information.

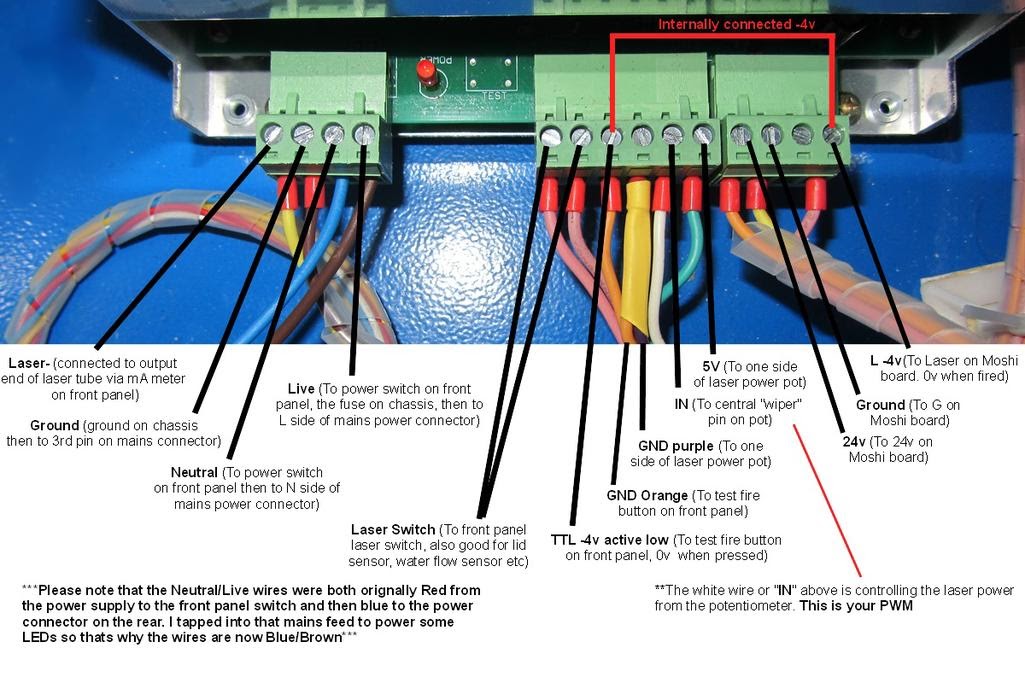

To break things with some authority, this is a useful reference. Note that the 'test' button fires the laser.