Difference between revisions of "Blacksmithing"

m (→Risk assessment) |

m (→Outline of working environment) |

||

| (2 intermediate revisions by the same user not shown) | |||

| Line 9: | Line 9: | ||

The forge will have a guard on the rear and chimney above to prevent debris from falling behind the work area and to ensure fumes are moved efficiently away from the work area. | The forge will have a guard on the rear and chimney above to prevent debris from falling behind the work area and to ensure fumes are moved efficiently away from the work area. | ||

| − | The Anvil is secured to the tree stump and | + | The Anvil is secured to the tree stump and has additional weight added in the form of chains, these also help to dampen the noise. |

The tools are placed on the tool bench and include all the tools needed for the intended job. | The tools are placed on the tool bench and include all the tools needed for the intended job. | ||

| Line 90: | Line 90: | ||

|Potential fire hazard, smoke exposure may lead to short and long term health issues. | |Potential fire hazard, smoke exposure may lead to short and long term health issues. | ||

|Large work surface area surrounding actual fire pot, and walled hood installed with chimney | |Large work surface area surrounding actual fire pot, and walled hood installed with chimney | ||

| − | | | + | |3 * 2 = 6 |

|Ensure charcoal forge is secure, steady and in good order before lighting. | |Ensure charcoal forge is secure, steady and in good order before lighting. | ||

|- | |- | ||

| Line 96: | Line 96: | ||

|Fire hazard to persons and property | |Fire hazard to persons and property | ||

|Forge has no enclosure so cannot trap gas to form an explosive mix. Burner prevents flame traversal into the gas line, as does the regulator and cylinder valve. | |Forge has no enclosure so cannot trap gas to form an explosive mix. Burner prevents flame traversal into the gas line, as does the regulator and cylinder valve. | ||

| − | | | + | |4 * 1 = 4 |

|Visually inspect equipment prior to use, checking valves function as expected during firing up | |Visually inspect equipment prior to use, checking valves function as expected during firing up | ||

|- | |- | ||

| Line 120: | Line 120: | ||

|Potential hazard for burns if someone doesn’t realise it was used recently | |Potential hazard for burns if someone doesn’t realise it was used recently | ||

|Members made aware that smithing has been taken place | |Members made aware that smithing has been taken place | ||

| − | | | + | |4 * 1 = 4 |

|Members to be trained to assume it is hot until proven otherwise. | |Members to be trained to assume it is hot until proven otherwise. | ||

|} | |} | ||

| Line 135: | Line 135: | ||

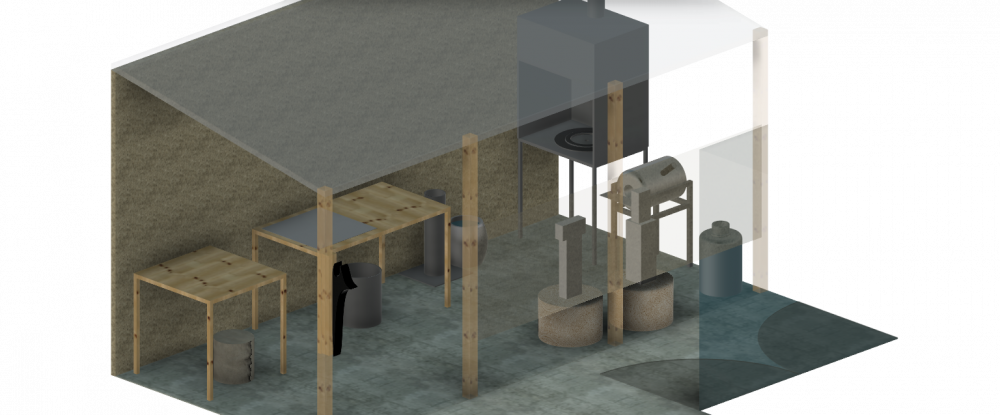

| − | [[File:4-example-forge-layout.png| | + | [[File:4-example-forge-layout.png|Example forge layout, some rearrangement likely as development progresses|1000px|thumb|left]] |

Latest revision as of 20:19, 24 July 2019

Contents

Method statement

Blacksmithing

Outline of working environment

The smithing will take place outside. The forge will have a guard on the rear and chimney above to prevent debris from falling behind the work area and to ensure fumes are moved efficiently away from the work area.

The Anvil is secured to the tree stump and has additional weight added in the form of chains, these also help to dampen the noise.

The tools are placed on the tool bench and include all the tools needed for the intended job. Method Statement Pre activity checks

- Ensure the work area and 5 meters surrounding area is clear of all rubble, loose articles, trip hazards and flammable items.

- All tools and equipment needed for the activity should be collected and stored safely nearby.

- Hammers

- Tongs

- Spare Coal Coke

- Metal to be forged

- Quenching bucket

- The equipment, including the forge itself, the anvil, hammers and tongs should be inspected to check they are not damaged and are in working order.

- All required PPE should be worn:

- Safety goggles,

- Sturdy Leather boots,

- Leather Apron or welders overalls,.

- No flammable synthetic clothes to be worn as these can melt and cause severe burns

- Optional PPE may be worn:

- Gloves, these can protect from burns but can also inhibit fine detailed work.

- Ensure you know where the fire extinguishers and sand buckets are.

- Ensure that you are knowledgeable on the particular requirements of the type of metal you are choosing to forge.

Activity

Light the forge using firelighters with the electric bellows on low. Ensure that the amount of coal used does not exceed the combustion area.

For the duration of the activity it is import to increase and decrease the airflow as required to control the size and temperature of the coals.

Ensure a long handle is attached to the metal being forged. Mild steel rebar served this purpose very well. Using the handle or tongs place the item in to the forge, increase airflow and temperature to heat the metal up to the desired temperature (this is generally related to its colour for given materials, mild steel is very forgiving though)

Take the material out and start to use a comfortable hammer to shape it, as it makes contact with the anvil and hammer heat will start to dissipate and it can often be seen to cool and harden. Reapply the item to the forge to heat it up again, repeat until the item is the desired shape.

It is expected that you should know what material you are using and whether or not it can be quenched without damaging it.

Post activity checks

- Collect up all tools to be put away

- Sweep and clear up work area of all mess.

- Close the vent to the coal to stop the oxygen draw.

- Using the fire poker open up the centre of the burning coal to allow heat to escape

- Continue to fire check for an hour after the forging has finished to ensure that the coal has gone out and cooled.

Risk assessment

| Hazard to health and/or safety present or possible | Potential risk to members & public | Precautions already taken | Risk Level (Severity x Likelihood) | Action Required, by whom and when? |

|---|---|---|---|---|

| Stray sparks or embers may ignite materials nearby | Possible fire hazard and all that that entails | Area cleared of wooden flooring, litter removed, wooden panel fence guarded by OSB, sand bucket, fire extinguisher, and hose point all nearby. | 4 * 2 = 8 | Check surrounding environment for stay flammable debris before commencing lightup |

| Injury to persons from hot debris, sparks, noise, and RSI | Burns, residual long-term effects on health | PPE available | 4 * 3 = 12 | Appropriate PPC to be provided. Cotton outer layer is essential, sensible leather footwear, eye protection (with side guards). Optional leather apron, leather or other suitable glove for tong hand. Visitors and spectating members to be a safe distance away. |

| Slip hazard from quenches | Possible falls, potentially near hot equipment or materials. | Quenches located at the edge of the work area, and sand available to absorb any spillage. | 3 * 1 = 3 | Ensure quenches cannot tip or spill, and that sand is available. |

| Hot metals cooling on bench, or tempering in sand bucket | Burns from attempting to pick up hot metals | Cooling area of workbench that users know to suspect residual heat in. Users trained to hoverhand any workpieces if in any doubt, regardless of location, and not to rummage bare-handed in the sand bucket regardless of expected temperature of metals. | 3 * 2 = 6 | Ensure that sand bucket is ‘flagged’ when hot metals are in it, by drawing a cross on the top of the sand. |

| Charcoal forge may shed coals or embers, and may smoke | Potential fire hazard, smoke exposure may lead to short and long term health issues. | Large work surface area surrounding actual fire pot, and walled hood installed with chimney | 3 * 2 = 6 | Ensure charcoal forge is secure, steady and in good order before lighting. |

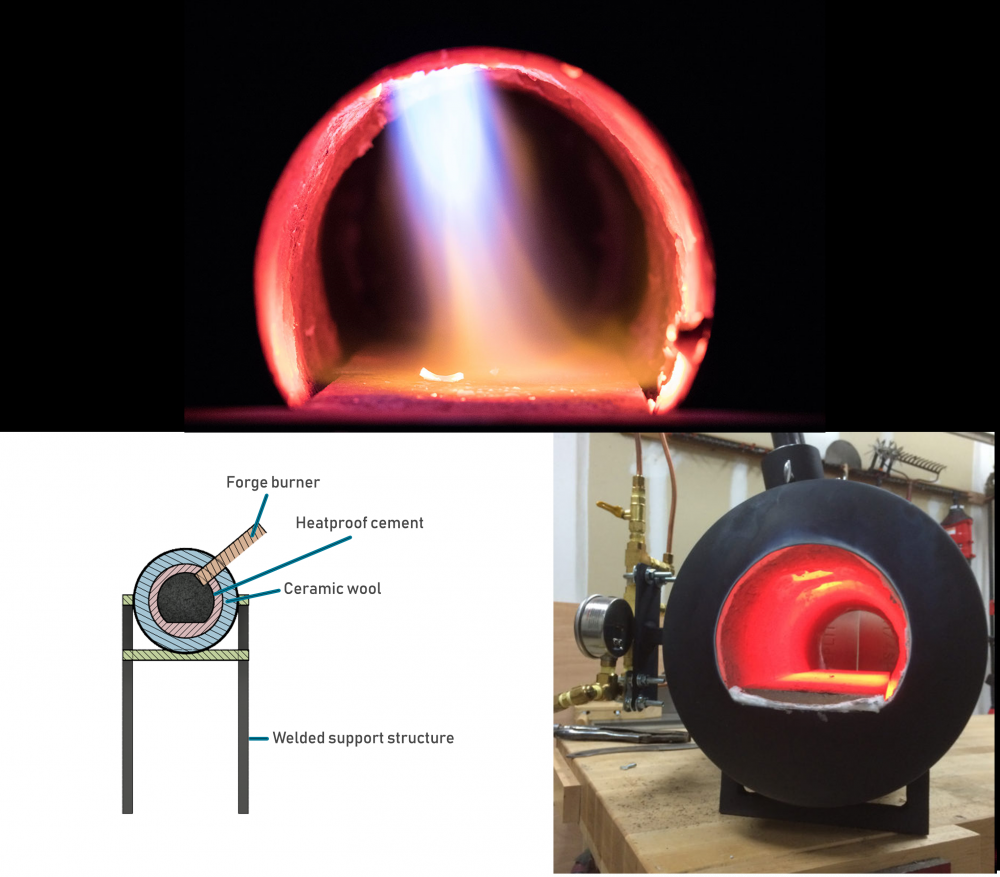

| Gas ‘explosion’ from propane forge, gas leak from equipment | Fire hazard to persons and property | Forge has no enclosure so cannot trap gas to form an explosive mix. Burner prevents flame traversal into the gas line, as does the regulator and cylinder valve. | 4 * 1 = 4 | Visually inspect equipment prior to use, checking valves function as expected during firing up |

| Sparks and noise from use of angle and belt grinders | Potential fire hazard, ear and eye damage, and particle inhalation risk, shattering discs. | PPE available, including glasses, ear defenders and dusk masks for use as appropriate. Full face shield available for angle grinding use, along with tool guards. | 3 * 3 = 9 | Ensure PPE is used as applicable, and grinder guards are not removed. |

| Hammering hot metal results in noise and hot sparks | Potential hearing damage, fire hazard, eventual RSI | PPE still available. Forge hours prevent RSI from occurring due to continuous daily use. | 3 * 3 = 9 | Ensure PPE is used as applicable. RSI can be prevented by using correct posture and technique when hammering. |

| Charcoal forge will remain hot for some time after use | Potential delayed fire hazard | Forge not left unattended while ‘active’, and regularly monitored during cooling to ensure it hasn’t misbehaved in some way. | 5 * 1 = 5 | Ensure building is not left until forge has been safely decommissioned. Forge hours will ensure time allows for this. |

| Propane forge will be hot for a relatively short time after use | Potential hazard for burns if someone doesn’t realise it was used recently | Members made aware that smithing has been taken place | 4 * 1 = 4 | Members to be trained to assume it is hot until proven otherwise. |

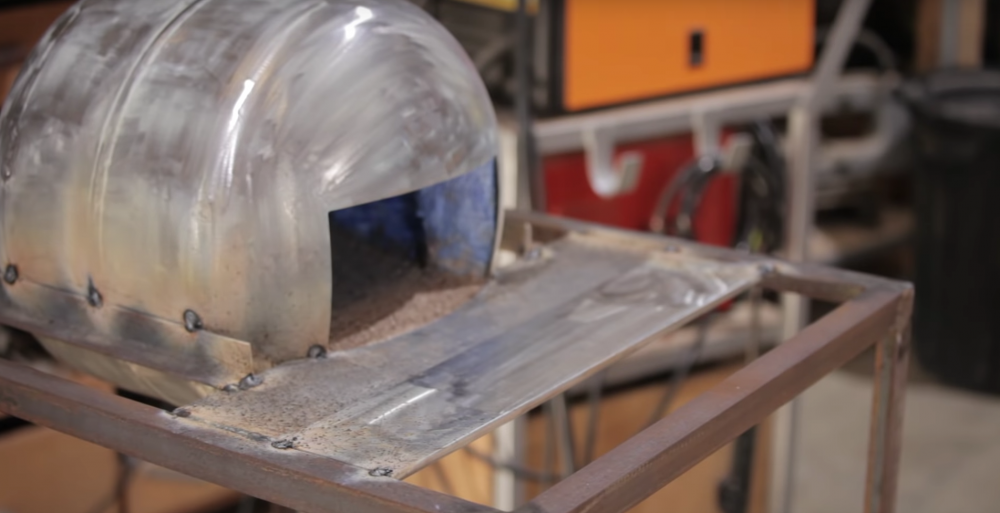

Forge construction process