Difference between revisions of "3D printers - general information"

m (Kellis moved page 3D printers to 3D printers - general information: Moved this to be a general information page with 3D printers having their own page) |

|||

| Line 3: | Line 3: | ||

We are now allocating 'owners' to the Makerspace equipment, these owners will be responsible for ensuring there are appropriate processes in place for things like maintenance, safety and training etc. The 'owner' for the 3D printers is '''Keith Ellis''', if you are having trouble using the printers, want to report a fault, need some training please speak to Keith or alternatively email your request to [mailto:ms_3dprinters@icloud.com ms_3dprinters@icloud.com] | We are now allocating 'owners' to the Makerspace equipment, these owners will be responsible for ensuring there are appropriate processes in place for things like maintenance, safety and training etc. The 'owner' for the 3D printers is '''Keith Ellis''', if you are having trouble using the printers, want to report a fault, need some training please speak to Keith or alternatively email your request to [mailto:ms_3dprinters@icloud.com ms_3dprinters@icloud.com] | ||

| + | ==Warning!== | ||

Please make sure you know what you are doing if you are using these printers, if you are unsure please ask for assistance. We would much prefer you ask the question rather than adjust something that has already been pre-set and calibrated. | Please make sure you know what you are doing if you are using these printers, if you are unsure please ask for assistance. We would much prefer you ask the question rather than adjust something that has already been pre-set and calibrated. | ||

'''Warning''', 3D printers work by heating up and melting plastic filament, the print beds and hot-ends/nozzles get extremely hot. '''DO NOT TOUCH''' any hot parts, some of the printers are bare bones and to allow them to work the hot areas are not protected. If you are unsure ask someone to help. | '''Warning''', 3D printers work by heating up and melting plastic filament, the print beds and hot-ends/nozzles get extremely hot. '''DO NOT TOUCH''' any hot parts, some of the printers are bare bones and to allow them to work the hot areas are not protected. If you are unsure ask someone to help. | ||

| − | We have several 3D printers available for use | + | ==Our Printers== |

| + | |||

| + | We have several 3D printers available for use, for specific information on each one see the links below: | ||

# [[3D printer - Creality CR10 | Creality CR10]] | # [[3D printer - Creality CR10 | Creality CR10]] | ||

| Line 15: | Line 18: | ||

# [[3D printer - da Vinci|da Vinci 1.0]] - currently not in service | # [[3D printer - da Vinci|da Vinci 1.0]] - currently not in service | ||

# [[3D printer - NFire Delta | NFire Delta]] - currently not in service | # [[3D printer - NFire Delta | NFire Delta]] - currently not in service | ||

| − | |||

| − | |||

==General usage information== | ==General usage information== | ||

| Line 22: | Line 23: | ||

Filament is expensive, so some best practices are suggested to minimise the opportunity for mishaps. Foremost, if you are printing multiple copies of an item, it's best to simply do one first to ensure it will print as you expect. Not much is worse than four almost perfect models, but all with the same unexpected defect or sizing error. | Filament is expensive, so some best practices are suggested to minimise the opportunity for mishaps. Foremost, if you are printing multiple copies of an item, it's best to simply do one first to ensure it will print as you expect. Not much is worse than four almost perfect models, but all with the same unexpected defect or sizing error. | ||

| − | + | When printing multiple items, remember that if one of them goes wrong, due to say bed adhesion issues, an extruder bump, filament feeding mishap, or other unexpected occurrence, that you will waste a lot of filament either by having to abort the job and losing the correct object(s), or having a huge pile of string building up where the printer believes it should be printing the missing object. So sometimes it's worth not batching, especially so for tall or delicate items. | |

| − | + | ||

| − | When printing multiple items, remember that if one of them goes wrong, due to say bed adhesion issues, an extruder bump, filament feeding mishap | + | |

===Charges=== | ===Charges=== | ||

Revision as of 15:13, 16 June 2019

We are now allocating 'owners' to the Makerspace equipment, these owners will be responsible for ensuring there are appropriate processes in place for things like maintenance, safety and training etc. The 'owner' for the 3D printers is Keith Ellis, if you are having trouble using the printers, want to report a fault, need some training please speak to Keith or alternatively email your request to ms_3dprinters@icloud.com

Contents

Warning!

Please make sure you know what you are doing if you are using these printers, if you are unsure please ask for assistance. We would much prefer you ask the question rather than adjust something that has already been pre-set and calibrated.

Warning, 3D printers work by heating up and melting plastic filament, the print beds and hot-ends/nozzles get extremely hot. DO NOT TOUCH any hot parts, some of the printers are bare bones and to allow them to work the hot areas are not protected. If you are unsure ask someone to help.

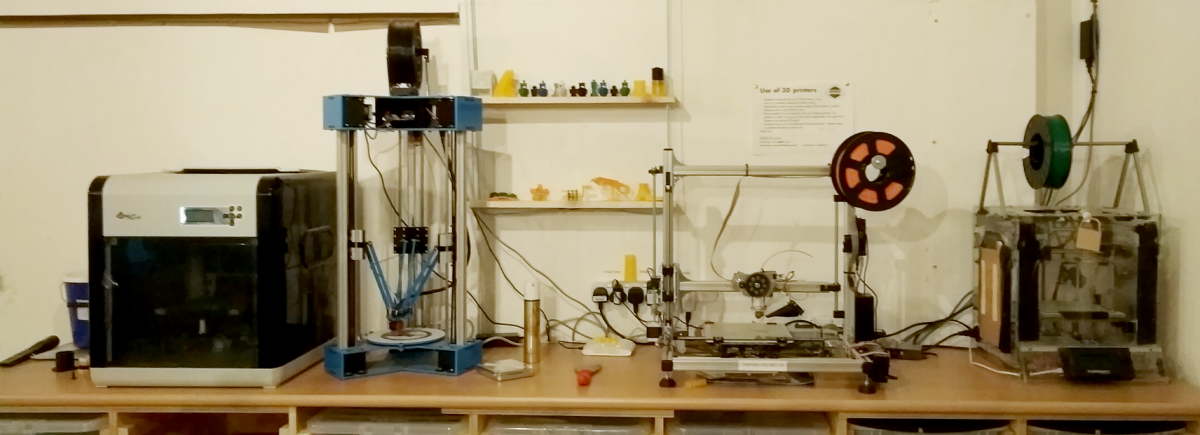

Our Printers

We have several 3D printers available for use, for specific information on each one see the links below:

- Creality CR10

- Monoprice Mini Delta

- Velleman K8200

- Turnigy Fabrikator - currently not in service

- da Vinci 1.0 - currently not in service

- NFire Delta - currently not in service

General usage information

Filament is expensive, so some best practices are suggested to minimise the opportunity for mishaps. Foremost, if you are printing multiple copies of an item, it's best to simply do one first to ensure it will print as you expect. Not much is worse than four almost perfect models, but all with the same unexpected defect or sizing error.

When printing multiple items, remember that if one of them goes wrong, due to say bed adhesion issues, an extruder bump, filament feeding mishap, or other unexpected occurrence, that you will waste a lot of filament either by having to abort the job and losing the correct object(s), or having a huge pile of string building up where the printer believes it should be printing the missing object. So sometimes it's worth not batching, especially so for tall or delicate items.

Charges

We do not charge for the use of the printers, but we do ask that you pay 5p for each gram of filament used. Scales are provided for weighing used material/prints. Thank you very much.

Training Material

This is work in progress, but here we keep the latest training material for the 3D printers

Octoprint

Octoprint is software that is specifically designed to control 3D printers. We currently have a Raspberry Pi hooked up the K8200 and Turnigy 3D printers which run Octoprint.

Access

Web based interface, currently accessible whilst connected to the Ipswich Makerspace network via

- http://192.168.1.20/ for the K8200

- http://192.168.1.21/ for the Turnigy

To login use the following details

- Username: IpswichMakerspace

- Password: raspberry

Features

- Web based interface, available from any web browser when connected to the Ipswich Makerspace network

- Manual control of X, Y and Z motors as well as bed and hot end heaters and extrusion motor, this is useful for pre-heating the bed and priming the print nozzle.

- Ability to upload gcode files and print

- gcode visualiser to allow review the print layer by layer prior to printing

- Ability to upload 3D stl files and produce gcode with the built in Cura slicer profiles

- Basic stl viewer

Using the in-built Cura profiles

Octoprint has a plugin architecture, one plugin installed is the Cura plugin. This allows Cura .ini files (which detail how the slicing is to carried out) to be uploaded and applied to .stl files allowing slicing to be carried out locally on the Pi from an stl file without needing to do the slicing separately.

The Cura profiles have been named in such a way that they describe the slicer settings.

The file name is made up in several pieces as shown below.

Printer name | Filament material | Hotend temperature | Infill percentage | Support settings | Platform settings

An example file name is:

K8200_PLA_190_I30_S0_P0

This translates as follows;

- K8200 - The printer name

- PLA - The fillament type

- 190 - Hotend temperature of 190 degrees C

- I30 - Infill at 30 %

- S0 - No supports

- P0 - No platform

the full range of options for supports are:

- S0 - No supports

- S1 - Support where touching Build plate

- S2 - Support everywhere

the full range of platform options are:

- P0 - No platform

- P1 - Print with brim

- P2 - Print with raft

Creating your own profiles

Firstly, it may not be necessary to create your own profile, if you have some requirements that are not catered for by the profiles already provided, then you can slice your own 3D files using your own slicer of choice and then uploading the gcode produced directly into Octoprint. this eliminates the need to slice within Octoprint.

However, if you think the slicing profiles could be supplemented then feel free to create your own, but please use the file name convention shown above.

Unfortunately the Octoprint Cura plugin is a bit picky about which Cura .ini files it accepts. If you want to create a Cura profile you must download Cura version 15.04 or earlier. the newer version will not work. Cura can be downloaded here, please note version 3.x.x is actually newer than 15.x.x, the newer 3.x.x will not work.

We have a Github repo for keeping our profiles, click here. Feel free to create a pull request to add profiles.

Booking time on the 3D printers

- Members have priority use of 3D printers, if you are not a member please ask before using

- Membership allows you to book usage of the printers in advance

3D printer booking procedure

Check the calendar for the printer you want to book to see if it is available

| Velleman K8200 | - | http://bit.ly/K8200_cal |

| Turnigy Fabrikator | - | http://bit.ly/Turnigy_cal |

If the time you are interested in is free, please make a request on the form here: http://bit.ly/Book_3D_printer